About Us

Factory Induction

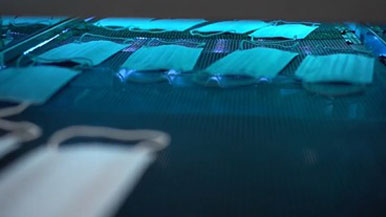

All people including production workers have to be conducted a full-body sterilization at air shower cleanroom, and then wearing masks, gloves, dust-free caps, dust-free shoe covers and protective clothing before entering the aseptic workshop.

It is the necessary passage for the goods to enter the sterile room. It can reduce the pollution problems caused by the goods entering and leaving the sterile room. The two doors of the cargo air shower cleanroom are interlocked, which can impel the function of air-lock chamber, to prevent the unpurified air from entering the sterile room. The clean air-stream filtered by the high-efficiency filter is sprayed onto the surface of object from rotatable nozzle from all directions, which removes dust particles effectively and quickly. The air with dust particles is filtered by the primary and high-efficiency filters, to re-circulate to the area of air shower.

Ethylene oxide (EO) is a broad-spectrum and low-temperature sterilant, which can kill various microorganisms, including spores, tubercle bacilli, bacteria, viruses, fungi, etc. at room temperature. With high level of penetration, EO can penetrate the micropores to reach the corresponding depth inside the product, thereby greatly improving the effect of sterilization.

The internal laboratory set up in the factory is capable of microbiological testing and related physical and chemical testing, such as microbiological indicators and residues of ethylene oxide can all be self-tested. The residues of ethylene oxide testing are to ensure the content of residual ethylene oxide in the mask is below the safety standard of 10ug / g. To ensure the quality of incoming raw materials and final product of masks, there are basic inspection instruments for examination, such as electronic scales, dynamometers, micrometers, Vernier calipers, rulers and whiteness meters.

In accordance with the relevant provisions of “Product Quality Law of The People’s Republic of China”, it has to establish complete inspection system for final products, such as strictly implementation on inspection rules of finished products, creating the management system of non-conforming product, stringent supervision for production at workshop in terms of workmanship, technical documents and standards.